FMEA is used to identify problems based on a detailed analysis of what the product consists of and what could cause issues.

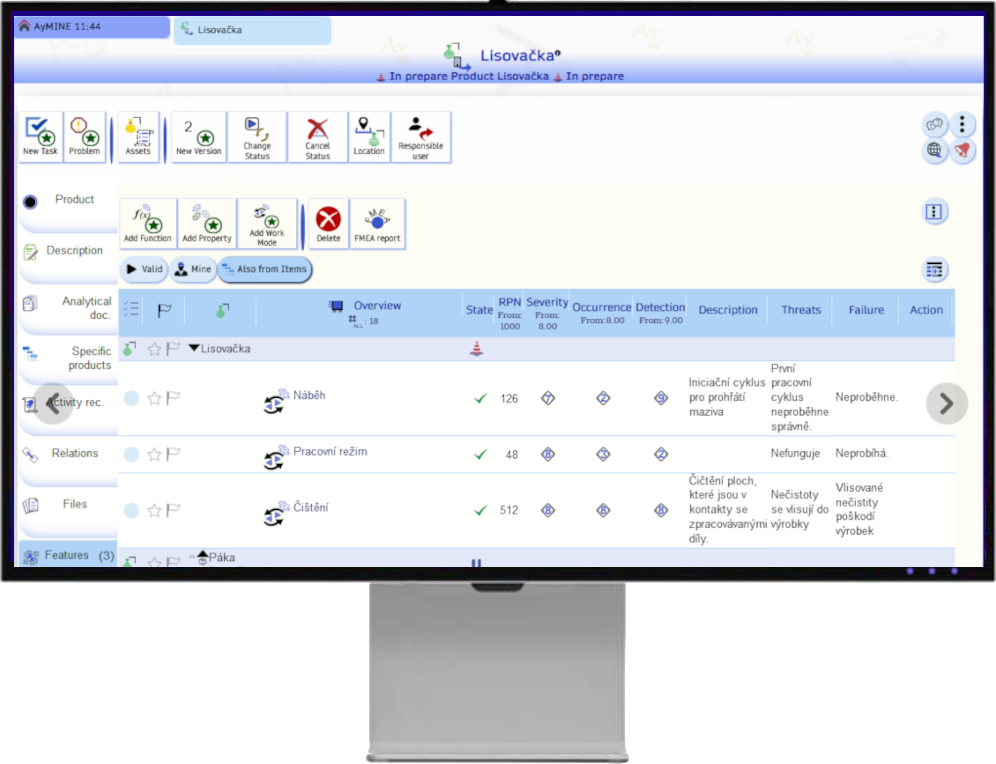

Support for FMEA in AyMINE System

See how to do a quality FMEA conveniently and correctly

FMEA for Quality Processes and Products

- Analysis of causes and effects of defects

- Analysis of potential defect occurrences and their consequences

FMEA for Production Process

It is closely related to the production process itself.

FMEA is conducted separately for individual parts of the production process and for the whole:

- For the development project itself (initial project FMEA)

- For the product (product FMEA)

- For planned steps of the production process

FMEA for Product

FMEA for the product allows analyzing, based on the structure of the product, what properties, functions, and operating modes each individual component of the product has.

Finding Risks and Countermeasures

For each individual function, operating mode, and property, the FMEA describes the risks if a failure occurs. These risks need to be evaluated.

- Probability of occurrence of the situation

- Ability to detect the problem in time

- Severity of the threat's impact on people nearby, especially their safety

Each of these values needs to be determined separately for each variable - the AyMINE system automatically pre-fills and calculates values, such as which property is "risky" in the product. For risks whose overall rating exceeds the threshold set for the product, measures to reduce them need to be established.

Documentation of the Analysis Subject

- For FMEA of the product, the analysis of the specific product description is the basis

- For individual production steps, the basic analyzed object is the individual tools and machines that will be used for production.

- For the production process itself, the description of individual steps, activities, and tasks is the basis

Proposing Measures to Minimize Risks

The most important output of FMEA are rationally justified requirements for the product or production equipment, new procedures, or control mechanisms that are incorporated into the production process (which includes control procedures). These requirements and procedures are part of the FMEA analysis.

FMEA Documentation

FMEA is documented both by the final report and by equally important documentation of its proper course:

- Records of the course of meetings, which prove when it took place and who participated

- Recorded comments on individual analyzed properties

- Documented resolution of these comments

- Requirements for products or processes

- New work steps within the methodology

- Records of all tasks performed as part of the FMEA process, including the work statement from participants